KTN-Clogworks 3D Printing Video

Demonstrating how Clogworks makes use of 3D printing technology.

KTN (Knowledge Transfer Network) approached us to demonstrate how Clogworks Technologies is using 3D printing and be a case study on how additive manufacturing can benefit companies of all sizes.

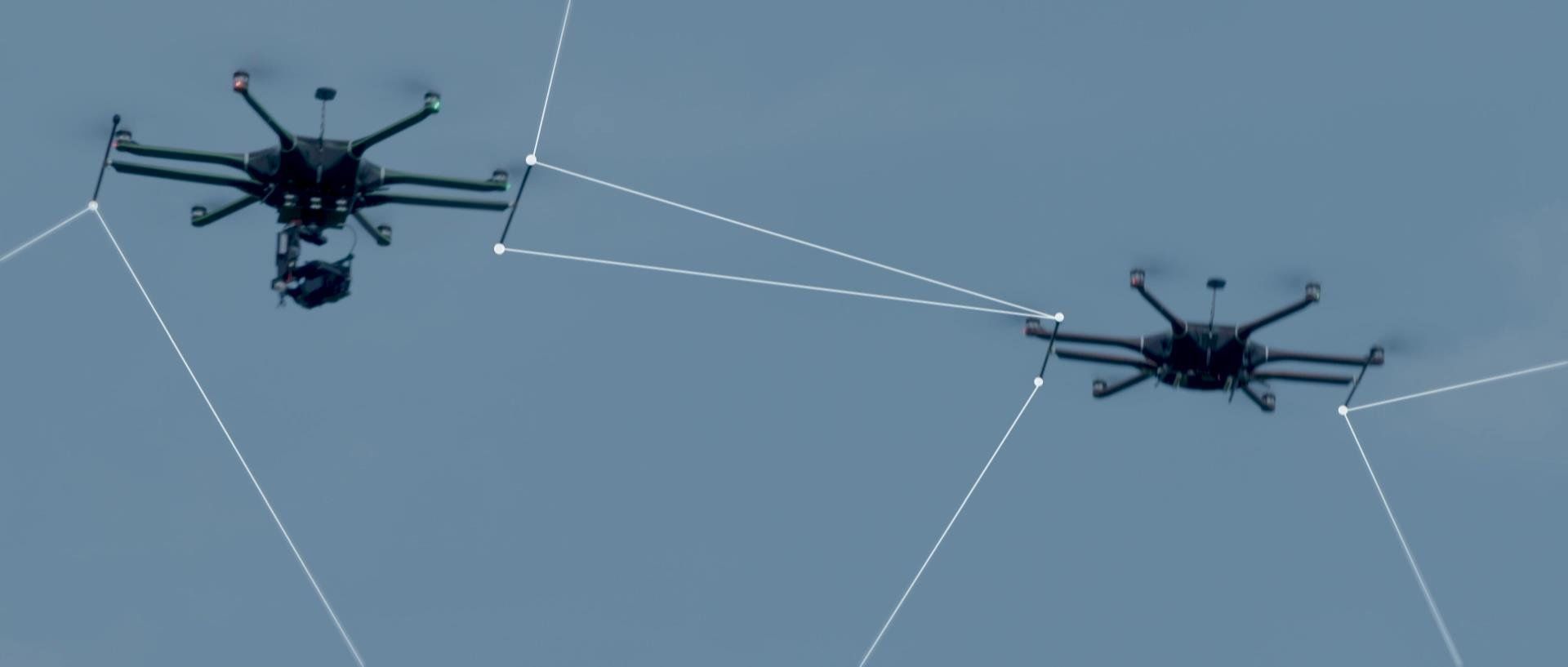

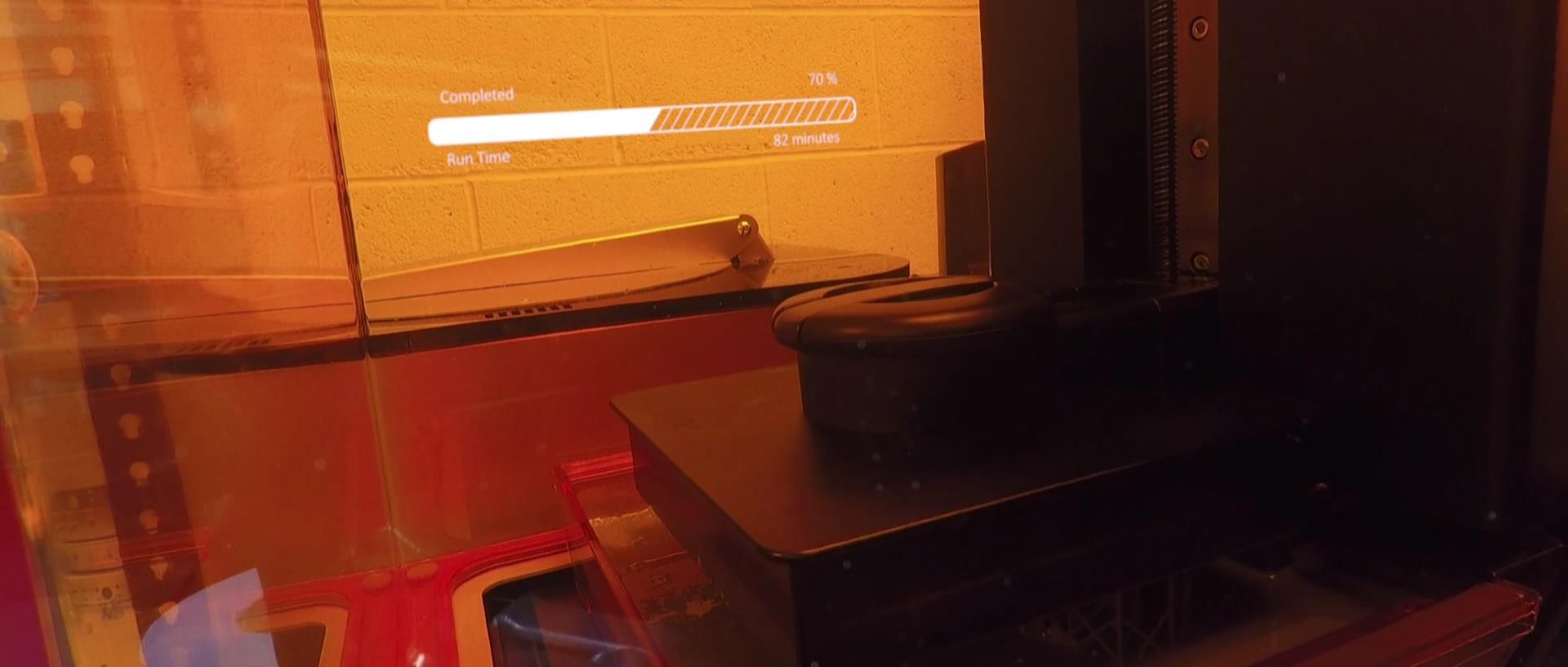

As a UK manufacturer of high quality precision engineered carbon fibre unmanned aerial vehicles (UAV/Drones) and accessories, the organisation constantly invest in innovation. In July 2017, Clogworks Technologies purchased a stereolithography (SLA) 3D printer to allow us to design, rapid-prototype and conduct small batch manufacture of plastic and rubber parts we use on the Dark Matter®products range. We also use it to facilitate all kind of payloads integration, as required by customers.

Two Clogworks® Dark Matter® hX multirotors were used for the video shoot and the aerial footage was captured using a GH4 Panasonic DSLR camera in a 3-axis gimbal. While using a single 22000mAh lithium polymer battery, this payload configuration allows for 25+ minutes of flight time. The Dark Matter® hX can accommodate up to two 22000mAh batteries when longer flight times are required.

We thoroughly enjoyed the 2 days video shoot with SVS Multimedia and OxyFire Media Creative. We are now pleased to announce the release of the official video in which Peter Opdam, Clogworks CEO & Founder, talks about our use of 3D printing and how it helps our constant pursuit for high quality while choosing the best materials and embracing new technologies.

Click to view the full video

Standard Operations

Unmanned Aerial Vehicles (UAV) applications range from the film industry to building inspections, wildlife research, agriculture, airborne delivery and security.

The Dark Matter® hX offers world-class performance with a long flight time (up to 45 minutes), operation in wind speed of up to 12m/s (26.8mph, 23.3knots, 43.2km/h) and flight speeds up to 20m/s (44.5mph, 38.9knots, 72km/h).

For aerial photography and video, the retract system allows for an unobstructed 360° view from the payload. Payloads of up to 7.5kg can be fitted thanks to a quick-release railing system, so the system offers excellent flexibility.

About Knowledge Transfer Network (KTN)

KTN has an Additive Manufacturing Special Interest Group (SIG) which aims to create and promote new knowledge and knowledge transfer in the area of additive manufacturing and 3D printing (AM/3DP), primarily for the benefit of UK business and economic growth and the Emerging Technology and Industries Team.

Knowledge Transfer Network is InnovateUK’s network partner and also provides innovation networking for other funders in line with its mission to drive UK growth. InnovateUK is part of UK Research and Innovation (UKRI), an executive non-departmental public body and the national funding agency investing in science and research in the UK.

About Clogworks Technologies

Clogworks Technologies is a UK manufacturer of high quality precision engineered carbon fibre unmanned aerial vehicles (UAV) and accessories. The organisation specialises in delivering UAV solutions to professional UAV operators involved in industrial, security and commercial applications, strive for great customer relations and constantly invest in innovation. For more information, please visit: www.clogworks.com.